UMF Forming DosingWrapping and CartoningMachine

UM-F represents a NEW Machine generation in the area of Cheese Portions.

The working process starts with the formation of the wrapping shells from

reel-fed sealing aluminum foil for subsequent filling of cheese in the dosing

station of the machine.

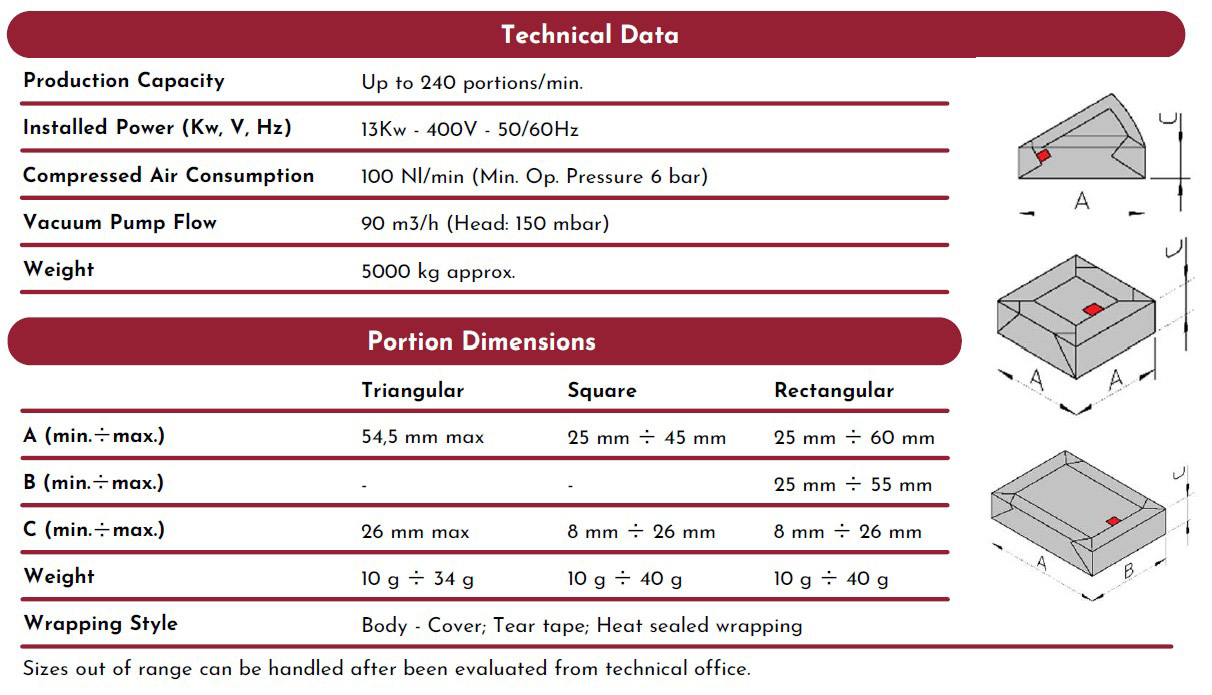

Production speed: approx. 230 ÷ 240 pcs/min *depending on product quality.

The paper design could be continuous printing or (option) electronically centered with an automatic system enable from

the panel. (NO print on the wrapping Film with Paper Labelling Station; pre printed label on the wrapping film for the

alternative without Labelling Station). Present machine able to work with /without Labelling station.

An automatic cutting device is foreseen for foil cuts at the proper size, equipped with electrical sensors to control anomalies

during the process, e.g. finished foil reel, avoid empty packs, etc.

The machine is equipped with an automatic cross-over tear strip application for the integral opening of the cheese portions.

A double piston device performs the shell forming where the Cheese will be dosed,: giving a significant improvement of SIGMA factor. PATENTED

- Compact footprint.

- Lubrication for life (“dry” machine bottom, means no oil consumption, no risk of stuck in lubrication pipes).

- Modern servo driven doser which significantly reduces the Standard Deviation (big product amount saving).

- Possibility of automatic weight correction (option with a check weigher with TREND correction).

- Double wrapping film holder with semi automatic reel change -splicing (option).

UM-F Cheese Forming Dosing

- Bigger reel size, thus guaranting higher rate of efficiency.

- Maintenance friendly (TPM).

- Increased cost saving for maintenance.

- 4.0 Industry compatible (IT connection compatible).

brochure